- Gradation compounding:The sealant layer of the protective membrane is a self-fusing special sealant: It is based on special functional rubber, Using the gradation compounding process, after the special functional rubbers of different molecular weights are directionally modified, they are graded and compounded, and then nanoscale or molecular-level blending is achieved through kneading and shearing, forming a special weather-resistant sealant with self-fusing function, which has excellent creep and adhesion properties at different temperatures.西牛皮防护膜与基面融合粘结密封,防漏防锈。 Xiniupi Protective Membrane bonds and seals with the base surface, preventing leakage and rust.

The Xiniupi Protective membrane is fused, bonded and sealed with the base surface to prevent leakage and rust.

The Xiniupi Protective membrane is fused, bonded and sealed with the base surface to prevent leakage and rust. - Fusion sealing:The sealant has the advantages of strong comprehensive performance such as high bonding force,irreversible bonding, and multi-interface bonding ability. Especially, it has excellent bonding characteristics with the metal base surface. Therefore, it can achieve sealing protection for the metal base surface and prevent the corrosion of the metal base surface by high-pressure water vapor and other corrosive substances.

Solving the common problems of traditional materials in the real environment: “Unstable bonding, short-term bonding, incomplete bonding”, "bonding first and then detaching"

Solving the common problems of traditional materials in the real environment: “Unstable bonding, short-term bonding, incomplete bonding”, "bonding first and then detaching"

- Technology 1

Self-fusing interface sealing technology

Giving the protective membrane excellent sealing function, preventing leakage and rust.

- Technology 2

inherent ultraviolet resistance technology

Enables the protective membrane to have excellent ultraviolet resistance performance, weather resistance and durability.

- Xiniupihe Xiniupi Protective membrane adopts the inherent ultraviolet resistance technology:

Rich in C-F bonds, it has excellent ultraviolet resistance. Ultraviolet rays cannot destroy its structure, and it is weather-resistant and durable. The Xiniupi metal roof protective membrane has excellent ultraviolet resistance capability and will not crack or age after long-term use.

The Xiniupi metal roof protective membrane has excellent ultraviolet resistance capability and will not crack or age after long-term use. - Other materialsOther materials are not intrinsically ultraviolet-resistant: They resist the damage of ultraviolet rays to their structure through external additives, and their lifespan is limited.

Many materials, in order to form or increase their ultraviolet (UV) resistance capabilities, attempt to achieve the UV resistance effect by injecting additives such as UV absorbers or shielding agents. However, their UV resistance capabilities and durability are related not only to the types and amounts of the external additives but also to the formulations and processing techniques of the materials.

Ordinary metal coatings have aged, cracked and delaminated under the action of ultraviolet rays.

Ordinary metal coatings have aged, cracked and delaminated under the action of ultraviolet rays.

Within5years

is the best window period

for the protection ofexisting metal

- Stage 1: Mild corrosionUsually appears in 1-3 years

Protection early warning periodPartial corrosion has occurred and timely protection is required

Protection early warning periodPartial corrosion has occurred and timely protection is requiredReddening rate: The rust area does not exceed10%

The corrosion is in the form of partial dots and linear corrosion at the lap joints

- Stage 2: Moderate corrosionAppears in 3-5 years

The corrosion has expanded and is in the early stage of accelerated corrosion, which is the protection window period."Within 5 years is the best window period for the protection of existing metal roofs."

The corrosion has expanded and is in the early stage of accelerated corrosion, which is the protection window period."Within 5 years is the best window period for the protection of existing metal roofs."Reddening rate: The rust area does not exceed50%

Rust points have formed a planar shape, and rust has appeared in patches

- Stage 3: Severe corrosionAppears in 5-10 years

The last rescue period for protectionMissing this period will enter the "terminal stage of cancer" and be hopeless

The last rescue period for protectionMissing this period will enter the "terminal stage of cancer" and be hopelessReddening rate: The rust area exceeds50%

A continuous rust surface has formed, and the corrosion rate has doubled

- Stage 4: Extremely severe corrosionMore than 10 years

The "full spread of cancer" stageHopeless. The panel strength is like bean curd dregs and loses the protection value. It can only be replaced and redone, but it still only treats the symptoms but not the root cause.

The "full spread of cancer" stageHopeless. The panel strength is like bean curd dregs and loses the protection value. It can only be replaced and redone, but it still only treats the symptoms but not the root cause.Reddening rate: The rust area reaches100%

The entire surface has rusted, with partial perforations, and the panel strength has been greatly reduced

01Xiniupi Self-Fusion Type Special Multi-functional Protective Membrane

01Xiniupi Self-Fusion Type Special Multi-functional Protective Membrane

02Special Purpose Interface Treating Agent Matched With Xiniupi Self-Fusion Type Special Multifunctional Protective Membrane

02Special Purpose Interface Treating Agent Matched With Xiniupi Self-Fusion Type Special Multifunctional Protective Membrane

03Joint Sealing Tape Matched With Xiniupi Self-Fusion Type Special Multifunctional Protective Membrane

03Joint Sealing Tape Matched With Xiniupi Self-Fusion Type Special Multifunctional Protective Membrane 04Joint Sealant Matched With Xiniupi Self-Fusion Type Special Multifunctional Protective Membrane

04Joint Sealant Matched With Xiniupi Self-Fusion Type Special Multifunctional Protective Membrane

4 steps for metal roof protection

1 rust fixation and 3 sealings-

Rust removal and rust fixation on the base surface to enable better integration of the protective membrane and the base surface

-

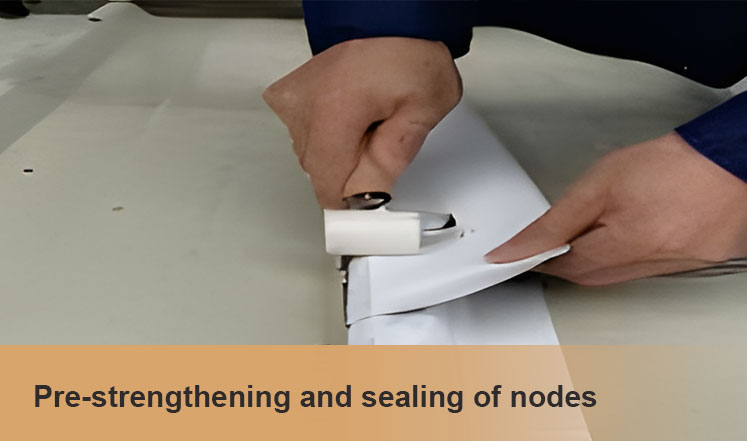

Before laying the protective membrane on a large surface, the essential parts such as nail holes and seams of the metal roof should be pre strengthened with sealing tape to ensure the sealing performance and reliability of the joint areas.

-

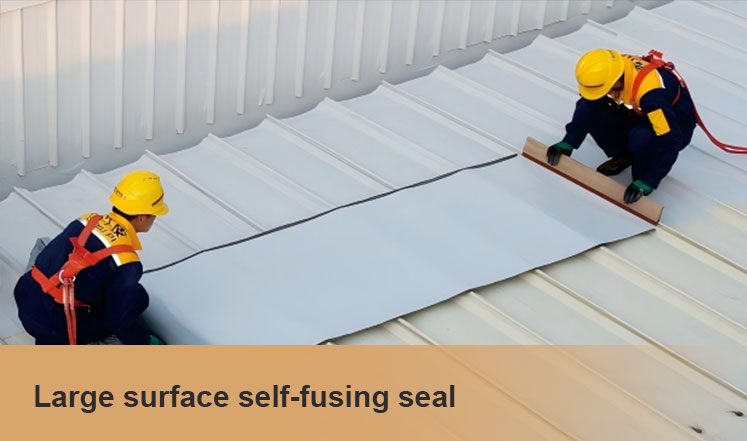

Use the self-fusing special function protective membrane to seal the large surface of the metal roof.

-

Fusing and bonding with the base surface to form an overall continuous seal and achieving overall protection effect.

-

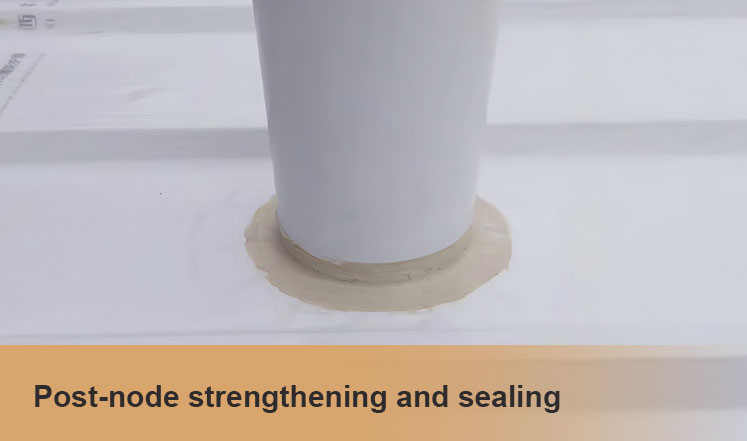

Strengthen the weak links and relevant points to provide an extra layer of protection for the nodes and joints.

- Flat shapeFlat shapeFor example:flat panels, lighting panels, deformation joints, etc.

Features:There are many joints, which are prone to deformation, and the risk of leakage is higher.- Lap joint parts

- Skylight panel parts

- Raised shapeRaised shapeFor example:Vibration is more obvious, and there will be more leakage points.

Features:Exhaust pipes, vent pipes, roof maintenance passages, etc.- Exhaust pipe parts

- Ridge parts

- Concave shapeConcave shapeFor example:There are many fixed points, and long-term moisture will lead to more serious rust.

Features:Gutters, eaves gutters, etc.- Eaves gutter parts

- Gutter parts

-

XINIUPI SF-CPS SELF-FUSION TYPE SPECIAL MULTIFUNCTIONAL PROTECTIVE MEMBRANE

The Xiniupi Self-Fusion Type Special Multi-functional Protective membrane is produced by using an ultra-weather resistant special function fluorocarbon composite film as the surface sun protection reinforcing layer, grading and compounding various special function rubbers to form a self fusing characteristic sealing adhesive layer, and using a high-barrier anti-adhesion release film as the isolation layer.

Download -

XINIUPI SF-CPS SELF-FUSION TYPE SPECIAL MULTIFUNCTIONAL PROTECTIVE MEMBRANE

Metal roofs are inherently "afraid of 3 things":Corrosion and leakage, which greatly shorten their service life. There are many existing maintenance problems for metal roofs. Traditional methods treat the symptoms but not the root causes. How can the maintenance of metal roofs be more effective? Comprehensive protection solution for metal roofs. 8-year university-enterprise cooperation for joint R&D.

Download