CPS Reactive Adhesion TechnologyA technology that enables synchronous curing, reaction and bonding between joint waterproofing sealant, waterproofing membrane and cement, making them integrate with concrete, thus achieving firm, irreversible and comprehensive sealing and waterproofing for concrete.

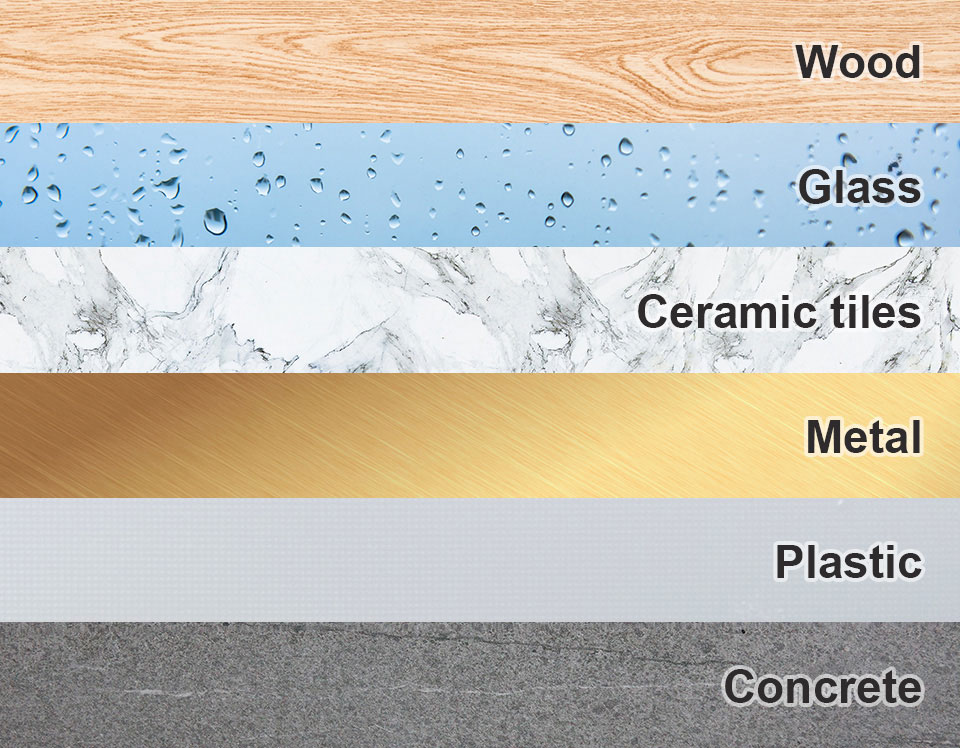

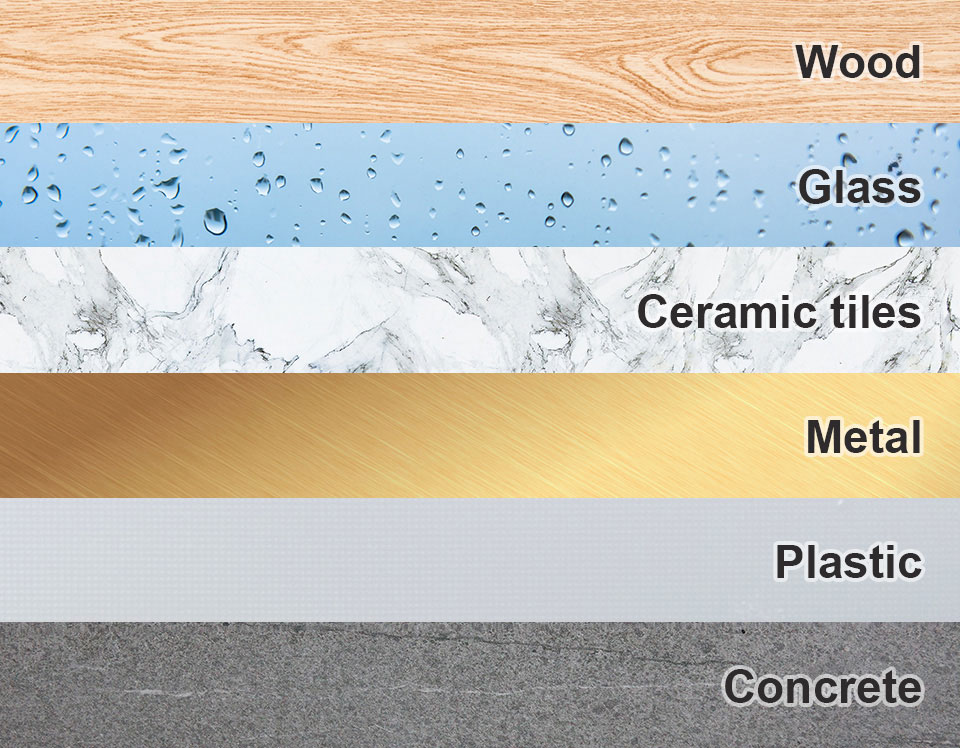

CPS Reactive Adhesion TechnologyA technology that enables synchronous curing, reaction and bonding between joint waterproofing sealant, waterproofing membrane and cement, making them integrate with concrete, thus achieving firm, irreversible and comprehensive sealing and waterproofing for concrete. Graded Composite Bonding TechnologyIt enables the joint waterproofing sealant to bond with various base surfaces in dry or wet environments, solving the problem of effective bonding and sealing at the interfaces with multiple materials such as metals, plastics (e.g., PVC pipes, etc.), and various membranes.

Graded Composite Bonding TechnologyIt enables the joint waterproofing sealant to bond with various base surfaces in dry or wet environments, solving the problem of effective bonding and sealing at the interfaces with multiple materials such as metals, plastics (e.g., PVC pipes, etc.), and various membranes. Rubber-based Waterborne Paste TechnologyA technology that turns rubber into a waterborne paste, which can form, bond and seal wherever it is applied; it solves the problems of easy flowing during vertical construction and difficulty in reaching the designed thickness.

Rubber-based Waterborne Paste TechnologyA technology that turns rubber into a waterborne paste, which can form, bond and seal wherever it is applied; it solves the problems of easy flowing during vertical construction and difficulty in reaching the designed thickness.

The invention patent for CPS Reactive Adhesion Technology (Patent No.: 200910114456.X) won the China Patent Excellence Award in 2014, which was the first China Patent Award ever received in the field of concrete sealing and waterproofing. The product based on this patented technology represents a revolutionary breakthrough in concrete sealing and waterproofing, filling the gap in this field and solving the global challenges in concrete sealing and waterproofing. It is a technology that enables synchronous curing, reaction and bonding between joint waterproofing sealant, waterproofing membrane and cement, making them integrate with concrete, thus achieving firm, irreversible and comprehensive sealing and waterproofing for concrete.

Easy to apply

Saves labor, time and effort

Easy to apply: ready to use upon opening the bucket, can be applied directly, dries and cures at room temperature, with simple operation;

Strong adaptability: can be directly applied on wet, uneven and various material substrates;

Simple subsequent operations: follow-up construction on the waterproofing layer is convenient, such as directly applying cement slurry, tiling, etc.

The sealing and waterproofing effect is outstanding.

Effective bonding and sealing: It can bond with various base surfaces in wet or dry environments, and effectively bond and seal with various materials such as concrete, metal, and plastic.

Anti-water channeling: It features strong bonding, comprehensive sealing and waterproofing, and has a self-healing function to repair the seal by itself.

Excellent crack resistance: It is rich in the elasticity and flexibility of rubber. Even if the base layer has slight cracks, the coating film can remain intact without affecting the waterproofing effect.

Reliable quality

Safe and environmentally friendly

Good film-forming effect: When applied on vertical surfaces, it does not flow, and the required thickness can be achieved with one or two coats/scrapes.

Excellent corrosion resistance: Suitable for use in environments subject to seawater erosion.

Green and environmentally friendly: It is a water-based material without volatile organic solvents, non-harmful, non-polluting, and conducive to health and environmental protection.

waterproofing of roof nodes

waterproofing of roof nodes waterproofing of basement nodes

waterproofing of basement nodes

waterproofing of bathroom nodes

waterproofing of bathroom nodes waterproofing of kitchen nodes

waterproofing of kitchen nodes

waterproofing of pile head nodes

waterproofing of pile head nodes

-

XINIUPI RUBBER-STATE WATERPROOFING PASTE

This product integrates Xiniupi's core sealing and waterproofing technologies: Reactive Adhesive Bonding Technology, Graded Rubber Technology, and Rubber Aqueous Paste Technology. It breaks through the limitations of traditional waterproofing materials by presenting as a viscous paste that forms a strong bond with interfaces of various materials, including concrete, metal, and plastic, achieving a sealed and waterproofing effect that resists cracking through creepage. It effectively resolves leakage issues caused by complex structures and diverse interfaces.

Download