- Xiniupi Waterproofing Technology Co., Ltd. has specialized in modern building waterproofing and protection for over 30 years and is a leading enterprise in China's concrete sealing waterproofing industry. In collaboration with Freudenberg High-Performance Materials Group and the research team of Professor Li Guangtao from Tsinghua University, it has developed the Yipinneng Reactive Adhesive Waterproofing Membrane. Additionally, the company has independently and successfully researched and manufactured the special precision equipment for the Yipinneng Reactive Adhesive Waterproofing Membrane.

- Freudenberg High-Performance Materials Group (Germany) masters the core technology for producing sheath-core structured hot-pressed cross-linked polymer carrier fabrics, and supplies over 500 million square meters of carrier fabrics annually for the manufacturing of high-end waterproofing coils worldwide. In 2018, Xiniupi Waterproofing Technology Co., Ltd. and Freudenberg High-Performance Materials Group signed a strategic cooperation agreement, successfully developing the polymer carrier fabrics dedicated to Yipinneng Reactive Adhesive Waterproofing Membrane.

- Professor Li Guangtao from the Department of Chemistry at Tsinghua University is a scientist specializing in supramolecular chemistry, molecular assembly, colloid and interface chemistry, and other fields. In 2006, Xiniupi Waterproofing Technology Co., Ltd. successfully developed the CPS Reactive Strong Adhesive Material for concrete sealing and waterproofing, which has been successfully applied for 16 years. In 2016, Professor Li Guangtao was appointed as the Chief Scientist of Xiniupi Waterproofing Technology Co., Ltd. He led Xiniupi's waterproofing research team to upgrade and improve the CPS reactive adhesive technology, and successfully developed the special adhesive for Yipinneng CPS-TS waterproofing membrane.

Xiniupi Precision Manufacturing

Xiniupi Precision Manufacturing Sheath-core Structured Hot-pressed Cross-linked Polymer Carrier Fabrics

Sheath-core Structured Hot-pressed Cross-linked Polymer Carrier Fabrics CPS Reactive Strong Adhesive Material

CPS Reactive Strong Adhesive Material

- Same Material, Premium SealingYipinneng Reactive Adhesive Waterproofing Membrane features consistent material for compatibility, uniform craftsmanship for connectivity, and conforming standards for consistent quality. Yipinneng meets the demand for premium full-sealing materials in concrete waterproofing.It avoids the common technical problem of incompatibility between the two materials and eliminates the management conflicts caused by the chaotic use of three mixed materials.

- Better Waterproofing with Full Sealing,Better with YipinnengIt reacts and bonds with different parts, and the waterproof layers are homogeneous and compatible, achieving long-lasting bonding and comprehensive sealing. The sheath-core structured hot-pressed cross-linked polymer substrate has enhanced performance, making the waterproof layer resistant to fatigue damage. Yipinneng for waterproofing ensures longer-lasting application.

- Adapting to All Concrete Structures, One Product with Multiple FunctionsIt can be applied using different methods and is suitable for applications in various parts; it is applicable to waterproofing projects such as underground, above-ground, and water tanks.

Yipinneng Reactive Adhesive Waterproofing Membrane bonds with cement concrete through the synergistic effect of physical tenon-and-mortise action and chemical reaction, forming an interface sealing layer that integrates with the main concrete structure. It provides comprehensive sealing for concrete structures, eliminating the persistent problem of water channeling and leakage.

Yipinneng Reactive Adhesive Wet-laid waterproofing Membrane

CPS Reactive Strong Adhesive Material adopts the CPS reactive adhesive interface Adhesive technology that has won two national awards. It can not only have a chemical reaction with concrete, but also ensure the long-term Adhesive between the waterproofing layer and the base surface and the sealing waterproofing without water channeling through the synergistic effect of chemical cross-linking and physical tenon; it "grows" with the base surface like flesh and blood, achieving full adhesion and sealing; at the same time, the skin-core structure hot-pressed cross-linked polymer base fabric is compounded with CPS Reactive Strong Adhesive Material, so that the waterproofing layer has balanced performance, being thin but strong, conformable and crack-resistant; it is thinner and more conformable, easy to apply; more tough and safer, not afraid of cracking.

The technology won the China Patent Excellence Award

ZL200910114456.X CPS Chinese Invention Patent: ZL200910114456.X CPS

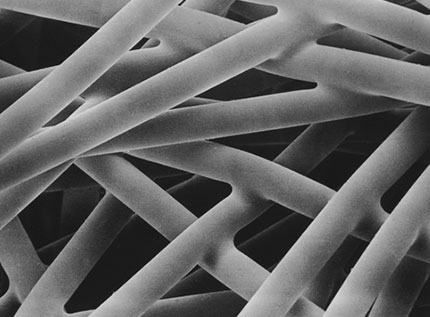

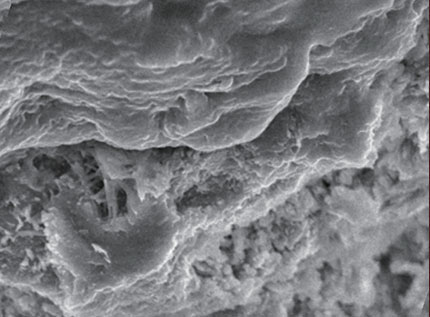

German Freudenberg high-performance base fabric is made of "skin-core" structure spinning through hot-press cross-linking process. The skin layer is made of PA, and the core layer is made of PET. The combined application of different materials, like the synergistic effect of elastic fibers and collagen fibers in the skin, "skin" and "core" share the force and disperse stress together, making it more elastic, tough and conformable with balanced performance. This makes the base fabric thin but strong, and the prepared waterproofing membrane has better adaptability, can conform to various building structures and form an overall sealed waterproofing layer.

We specialize in building waterproofing repair services, identifying the causes of waterproofing layer failure and discovering the effective elements of waterproofing layers.

We provide technologies and materials for effective building waterproofing layers, and study the causes of concrete water leakage as well as solutions to address such leakage.

-

2004The concept of sealing waterproofing is proposed, pointing out the correct direction for concrete waterproofing.

-

2006The invention of CPS reactive bonding technology (which obtained national invention patent authorization in 2011) has laid the technical foundation for sealed waterproofing.

-

2008The invention of CPS reactive bonding membrane provides material guarantee for concrete sealing waterproofing.

-

2010The concept of fully-sealed waterproofing is put forward, which improves the conceptual system of concrete waterproofing.

-

2014The invention of CPS joint sealing paste has filled the material gap in full-sealed waterproofing joint sealing.

-

2018The invention of CPS on-site fabricated waterproofing membrane provides an entirely new solution for concrete sealed waterproofing.

-

2021We develop new Yipinneng products to make waterproofing more compatible and longer-lasting.

Reactive Adhesive Type Skin-Core Structure Hot-Pressed Cross-Linked Polymer base fabric

- Specifications

1.5mm Double-sided Adhesive *20㎡; 2.0mm Double-sided Adhesive *15㎡

- Application Process

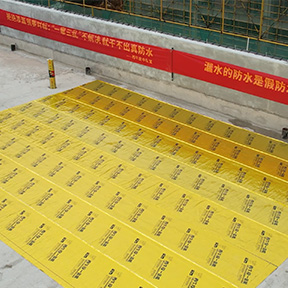

When single-layer laying of skin-core structure hot-pressed cross-linked polymer base fabric wet-laid waterproofing membrane, the wet-laying method is mainly adopted:

substrate Treatment → Sealing Treatment of Detail Nodes → Preparation of Cement Paste → Laying Membrane → Removing Paste and Exhausting → waterproofing Layer Curing,

For multi-layer laying, the first layer should be applied by wet-laying method, and the subsequent membrane waterproofing layer can be applied by self-adhesive method or wet-laying method. - Scope of Application

It is applicable to waterproofing projects of industrial and civil buildings, subways, tunnels and underground comprehensive pipe corridors, etc.

-

Residential Buildings

Residential Buildings -

Commercial Buildings

Commercial Buildings -

Underground structure

Underground structure -

subway

subway -

tunnel

tunnel -

roof

roof -

pipe corridor

pipe corridor -

It is applicable to waterproofing in new construction and renovation projects of existing buildings in architectural and municipal engineering as well as industrial buildings, such as basements, roofs, pipe corridors, subways, tunnels, pools, etc.

It is applicable to waterproofing in new construction and renovation projects of existing buildings in architectural and municipal engineering as well as industrial buildings, such as basements, roofs, pipe corridors, subways, tunnels, pools, etc.

-

XINIUPI YIPINNENG REACTIVE ADHESIVE WATERPROOFING MEMBRANE

Yipinneng Reactive Adhesive Wet-laid waterproofing Membrane (i.e., Yipinneng CPS-TS Reactive Adhesive Type Skin-Core Structure Hot-Pressed Cross-Linked Polymer Matrix Wet-laid waterproofing Membrane) is a new type of sealing waterproofing material specialy developed for the characteristics of domestic concrete building structures. One category of it can achieve the overall sealing waterproofing effect for all environments and all parts of concrete buildings. It is composed of a skin-core structure hot-pressed cross-linked polymer matrix (hereinafter referred to as: skin-core structure strong reinforcement) and CPS Reactive Strong Adhesive Material.

Download -

XINIUPI YIPINNENG REACTIVE ADHESIVE WATERPROOFING MEMBRANE

The'Three Golden Standards'for Effective Waterproofing of Concrete Structures. Three Breakthroughs in Yipinneng Waterproofing Technology Fully Aligned with the "Three Golden Standards" for Effective Waterproofing. Solve the Three Major Flaws of Traditional Waterproofing. Yipinneng Can Solve All Building Waterproofing Problems. International Cooperation, Focused for 8 Years, and Joint Development.

Download